Safety first

New certification and safety standards set course for development of ammonia as marine fuel

The certification framework for using ammonia as a fuel is starting to come together. Among recent developments classification society Bureau Veritas has granted approval in principle (AiP) to Swiss marine power company WinGD’s X-DF-A dual-fuel engine’s safety concept.

The safety concept describes how risks associated with using ammonia as a fuel are controlled under reasonably foreseeable abnormal conditions, as well as possible failure scenarios and their control measures.

It is therefore a key element for demonstrating a safe engine room concept and the capability for safe vessel operation using ammonia as fuel.

WinGD Director Sales Volkmar Galke commented: “Our steady and systematic approach to the new fuel technology coupled with collaborative efforts with esteemed partners like Bureau Veritas, reaffirms our commitment to safety, reliability, efficiency, and sustainability. This latest AiP underscores WinGD’s leadership in introducing carbon-free ammonia power to the deep-sea fleet. Teaming up with expert partners, such as BV, ensures that these cutting-edge technologies will be available well ahead of emission targets, providing operators with essential planning space and valuable hands-on experience.”

Bureau Veritas’s Senior Vice President, Marine & Offshore North Asia & China, Alex Gregg-Smith, emphasised the crucial need for trust in new technologies within the maritime industry’s ongoing evaluation of diverse transition pathways. He said, “This AiP instils confidence in early adopters that, subject to careful considerations in design, build, integration, and operation, the ammonia two-stroke engine can effectively address the rising demand for sustainable solutions. BV is proud to have collaborated with WinGD on this groundbreaking development.”

The AiP follows confirmed orders for X-DF-A in two bore sizes. The first engine to be developed, the

52-bore X52DF‑A, will be available for delivery from Q1 2025 and is applicable to a range of vessels including gas and bulk carriers.

WinGD noted: “As the industry moves at an accelerated pace towards a carbon-free future, the safety concept AiP is among the necessary steps giving shipowners the assurances they need to move ahead with ammonia-fuelled vessel designs. X-DF-A engines will operate on the Diesel principle in both diesel and ammonia modes, maintaining the same rating field as WinGD’s existing X-engines.

Meanwhile the International Association of Classification Societies (IACS) has recently adopted a New Unified Requirement (URH1) on Control of Ammonia Releases on Ammonia Fuelled Vessels.

An IACS statement explained: “In recent years, ammonia has emerged as one of a number of promising carbon-free fuels due to its high energy density and its ability to be liquefied at ambient temperatures. While ammonia therefore has a significant potential as a marine fuel it also presents safety challenges as it is highly toxic to human and aquatic life and it is therefore imperative to address the permissible limits to human exposure in ensuring the safety of onboard personnel. In light of this and with the aim of guiding the industry in its development of early projects using ammonia as fuel, IACS has developed a Unified Requirement (URH1) covering the release of ammonia from the onboard systems for bunkering, storing, preparing and using ammonia as fuel.”

IACS URH1 aligns with the Recommendations from US National Institute for Occupational Safety and Health (NIOSH) and establishes that an Ammonia concentration of 300 ppm or more is immediately dangerous, and a concentration of 25 ppm or more is dangerous if the exposure is longer than 8 hours. Additionally, it requires the system dealing with ammonia to be designed so as to prevent a direct release of ammonia to the atmosphere during normal operations and also, when possible, during any reasonably foreseeable abnormal scenario.

URH1 covers a number situations where a direct release is unavoidable under either a normal or abnormal scenario (such as the activation of a tank pressure relief valve). Among other design features it requires that the points where ammonia is expected to be released must be identified by the designer in a risk assessment and to be listed in the ship design documentation. The concentration resulting from such releases must not exceed a safe concentration (25 ppm) at locations of the ship accessible to the crew and this is to be demonstrated through gas dispersion analysis. This requirement is expected to result in the establishment of “toxic areas” (similar to hazardous areas on tankers) with access restrictions and other precautions, such as the absence of air intakes in that area.

IACS Secretary General, Robert Ashdown said: “URH1 on the control of ammonia releases on ammonia fuelled vessels is a first, but significant, step in providing industry with enhanced levels of assurance for this new fuel type and will be supplemented with further complementary guidance in due course. This work, together with the other work-streams underway within our Safe Decarbonisation Panel, demonstrates IACS’ strong commitment to ensuring that safety remains at the forefront of the maritime industry’s efforts to meet its decarbonisation targets.”

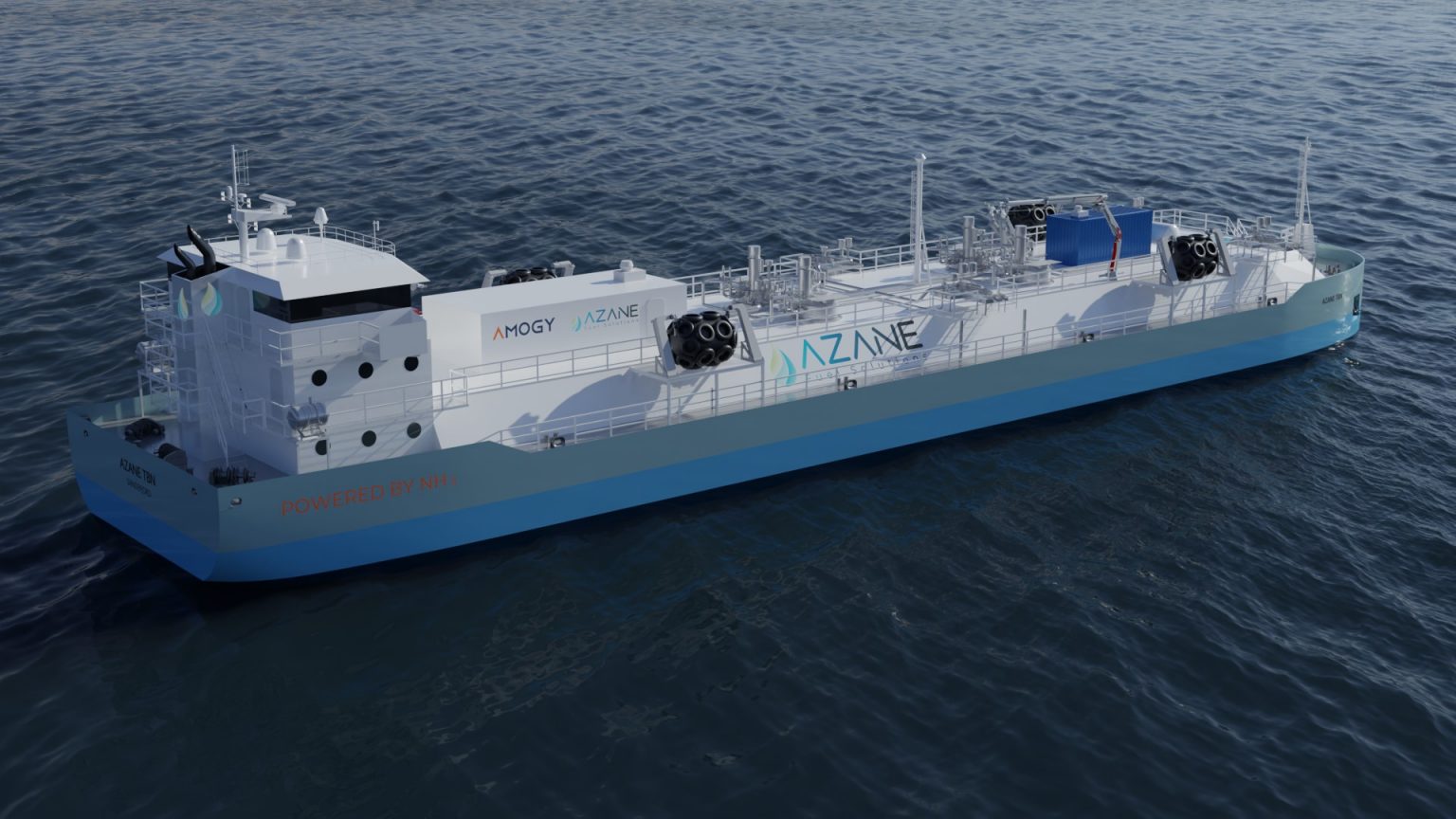

In a separate development, Norwegian company Azane Fuel Solutions has launched an ammonia bunker vessel design and signed an MoU with ammonia-to-power Amogy with the intention of including a zero-emissions power system for ammonia fuel onboard.

Azane has developed an ammonia fuel bunker vessel concept with a complete ammonia cargo handling system. The company is now looking for solutions to enable carbon free propulsion of the ammonia bunker vessel. When fully developed, Azane plans to offer the ammonia bunker vessels to ports including Hamburg, Rotterdam, Antwerp, Singapore and other key ports.

Image Credit: Azane

get

in touch

Constructive Media

Constructive Media

Hornbeam Suite

Mamhilad House

Mamhilad Park Estate

Pontypool

NP4 0HZ

Tel: 01495 239 962

Email: ibia@constructivemedia.co.uk

On behalf of:

IBIA London Office

Suite Lu.231

The Light Bulb

1 Filament Walk, Wandsworth

London, SW18 4GQ

United Kingdom

Tel: +44 (0) 20 3397 3850

Fax: +44 (0) 20 3397 3865

Email: ibia@ibia.net

Website: www.ibia.net

Emails

Publisher & Designer: Constructive Media

ibia@constructivemedia.co.uk

Editor: David Hughes

anderimar.news@googlemail.com

Project Manager: Alex Corboude

alex@worldbunkering.net